Simpson Doors

A Century of Excellence

Since 1912, Simpson has been designing some of the finest doors in the industry. Generations of families have dedicated their lives to Simpson and helped produce doors that are as aesthetically pleasing as they are durable. At Simpson the entire process, from the forest to your front door, is a team effort – with innovation, creation, and a wealth of experience at the forefront. When you select the perfect Simpson door for your home, you are receiving not only an expertly crafted product, you are receiving a piece of some of the finest design and engineering in the business.

Simpson’s outstanding line of interior and exterior doors includes a multitude of standard options – from panel to French to wonderfully decorative entry doors with matching sidelights and transoms. Available in an array of wood species, sizes, and glass options, Simpson affords its customers a custom-made door that provides more than just elegance and curb appeal to your home – it withstands the test of time.

Key Benefits: Simpson Doors

- Award Winning Windows

- Energy Efficiency

- Strong Warranty

- Resale Value

Simpson doors Project Ideas & Inspiration

No matter how big or small the job is, Simpson doors can help. Whatever you desire, Simpson offers a variety of styles, colors and options to meet any homeowner’s needs.

Doors Series

Simpson doors finishing

Simpson doors finishing options

Because Simpson doors are crafted with some of the finest materials in the industry, you can choose from a wide variety of stain or paint possibilities. If you choose paint instead of stain, you can apply either oil-base or acrylic resin-base paints over an oil-base primer. However, take care in following the finishing instructions provided here. Also, be sure to evaluate the conditions your Simpson door must endure, such as direct exposure to harsh climates, before deciding on the specific finish to use. All Simpson doors must be finished shortly before or after installation.

CAUTION: If during the finish process you are having issues and/or identify problems with your door, stop finishing immediately and contact the company from where you purchased your doors.

Simpson doors exterior finishing

Stain-and-Clear Finish

The recommended process for finishing Simpson doors is a 3-step process. Step 1: application of a wood conditioner. Step 2: application of a stain. Step 3: application of at least three top coats of a clear finish. When selecting the finishes for these three steps, select products that have been designed to work together.

A wood conditioner prepares the wood to accept finish uniformly and helps to spread the finish evenly.

Stains are available in a wide range of colors. Whatever color you select should have an alkyd-resin base. Under no circumstances should a lacquer-based finish system be used on exterior doors.

The three (minimum) top coats may be a solvent-borne (oil-base, alkyd resin-base, polyurethane resin-base) or a water-borne (acrylic resin-base) clear finish. See notes (1) and (2) below.

The advantages and disadvantages of solvent-borne vs. water-borne clear finishes are as follows:

- Solvent-Borne Advantages: Cures faster, harder and more water resistant. May be applied under variable weather conditions. Disadvantages: Subject to ultraviolet degradation and not as flexible or durable as water-borne clear finish.

- Water-Borne Advantages: Very flexible, greater ultraviolet resistance, and good exterior durability. Disadvantages: Cannot be applied below 50º F, long curing period required, and may not fully cure for several weeks. Water-sensitive until cure is complete.

NOTE: Do not sand between coats of clear acrylic. All stain-and-clear finishes will perform measurably better if protected from the direct effects of sunlight and weathering, and refinishing will not be required as frequently.

Paint Finish

Either oil-base or acrylic resin-base exterior grade paints may be used with success on panel doors. Oil-base paints offer more resistance to the passage of water (liquid and vapor) than acrylic resin-base paints, but the latter have better durability and color retention.

Doors should be sealed with a good quality oil-base primer followed by two top coats of either an oil-base or acrylic resin-base paint. Of course, both primer and top coat should be made by the same manufacturer and designed to be used as a combination.

NOTE: Where possible exposure to direct sun or rain is a factor, to keep your wood doors beautiful they require periodic resealing or painting dependent on weather or moisture exposure. Do not use dark colored stains or paint on doors exposed to sunlight, as some expansion and contraction of door parts may occur. Further, a dark colored stain or paint can void the door’s warranty.

CAUTION: Simpson Door Company cannot evaluate all the available paints and stains, nor the customers’ specific application requirements. Your paint dealer should know of suitable finish systems that give satisfactory results in your region. It is highly recommended that top quality finishes be selected, and the application instructions on the container be followed explicitly.

High Exposure Finishing

- Use an oil-based primer followed by at least three top coats of a high quality oil or acrylic-based paint on the exterior. Acrylic is more durable and has better color retention.

- Use a silicone or caulking bead (must be compatible with paint) around the perimeter of each glass pane. This will seal the putty and prevent any moisture from running directly into the door.

- Ensure all finish coats are allowed to flow into the glass area at least 1/16″.

- Ensure all coatings that go on the surface of the door are also applied to the top and bottom. Coat all six sides of every door, or your warranty will be voided.

- Silicone the door bottom sweep onto the bottom of the door and apply a surface mount drip cap to the bottom of each door to allow for moisture runoff onto the sill.

- For outswing units: Prior to finishing the top of the inactive door, be sure to fill the mortise pocket around the flush bolt prep with silicone or caulking. Moisture has a history of pooling up in this area on outswing units. Consider a thin layer of metal across the top of the door to keep moisture from direct contact with the wood.

- Storm or screen doors may be mandatory to completely eliminate moisture problems. Storm doors must be vented to eliminate temperature build-up.

- Performance Series® upgrades are recommended for high exposure door openings. Request WaterBarrier® and UltraBlock® technologies from your Simpson retailer to get the most life out of your door. And if you are selecting a french door, we strongly recommend specifying Simpson’s WaterBarrier technology.

Paint Finish Specifics

- “Bridge” finish from face of door to moulding, ensuring there is no gap between moulding and surface of the door.

- “Bridge” finish as noted above on inside of panel area where moulding meets panel and/or glass.

- Ensure all moulding miters are well-coated, leaving no gaps.

Jamb-to-Sill Specifics

- Caulk at sill-to-jamb leg connection.

- Use corner pads where sill meets jamb.

- Flood flush bolt hole in sill with caulk or silicone.

Simpson doors interior finishing

Stain-and-Clear Finish

A solvent-borne or water-borne finish system can be used for interior doors and may be a lacquer-based system. If a brush application is to be used, it is recommended that a presealer be used prior to staining. For best performance, a minimum of two clear top coats should be used over stains.

Paint Finish

Doors should be sealed with a good quality bare wood primer followed by two top coats of a solvent-base or acrylic enamel.

Energy Efficiency/NFRC Testing

Simpson is constantly striving to supply their customers with the most beautiful and efficient doors possible. Their research and engineering efforts have been a major reason why Simpson doors continue to perform well while retaining the classic beauty that has become synonymous with the Simpson name.

Over the years, Simpson has received questions from many of its customers regarding energy efficiency. Here are answers to some of the most common questions, as well as a summary of the most recent NFRC testing results for Simpson’s doors.

Is wood an energy-efficient building material?

According to the Temperate Forest Foundation, wood is 16 times more efficient as an insulator than concrete, 415 times as efficient as steel and 2,000 times as efficient as aluminum. And wood is the only truly sustainable resource as forests are able to regenerate themselves within our lifetime.

What can I do to make my entryways more energy efficient?

The majority of heat loss in an entryway occurs around the door rather than through the door. Therefore the most important considerations for energy efficiency are how well the door has been hung and the quality of the application of the weatherstripping. Take great care during these steps or hire a professional to do the work for you.

Does Simpson offer special glazing options for doors with glass?

Simpson offers insulated glass (I.G) units and argon-filled and specially coated units to meet virtually all climate considerations. A Simpson Authorized Dealer will be able to assist you in determining what options work best for your specific needs.

What is U-Factor?

U-Factor is the measurement of how well a building material—typically windows and doors—keeps heat inside of a building or home. The lower the U-Factor, the greater the door’s resistance to heat flow and the better its insulating factor.

What is SHGC?

Solar Heat Gain Coefficient (SHGC) measures how well a product blocks heat by sunlight. SHGC is expressed as a number between 0 and 1. The lower the SHGC, the less solar heat is transmitted.

WHAT IS VT?

Visible transmittance (VT) is an optical property that indicates the fraction of visible light transmitted through a door. The lower the VT, the less light is transmitted.

WHAT IS AL?

Air leakage (AL) is a measure of heat loss and gain through cracks in the door assembly. It is expressed as the equivalent cubic feet of air passing through a square foot of window area. The lower the AL, the less air will pass through cracks in the door assembly.

Glass Options Available

Now when you order an impact-resistant door, you don’t have to settle for clear glass. You have a variety of textured glass options to choose from including:

- Cross Reed

- Delta Frost

- Narrow Reed

- P-516

- Rain

- Satin Etch

- Seedy Baroque

- Clear Laminate

- White Laminate

- Out-swing Doors

- In-swing Doors

-

Any Wood

Select the wood species that fits you. Choose from an array of species, from traditional to exotic, each meeting our strict

grading standards. -

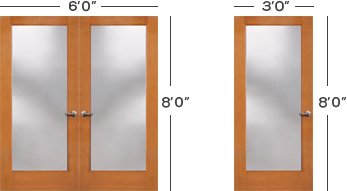

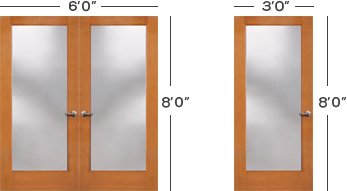

Any Size

Our doors come in all shapes and sizes. Select your size up to 10 feet tall, 6 feet wide and 2-1/4″ thick.

-

Glass Options

Let your glass reflect your life. We offer a variety of textured and obscure glass options to fit your personality.

-

Caming Choices

From silver to black to brass, opt for the style of caming—commonly referred to as “leading”— that best complements your style.

-

Privacy Rating

You can let the world in or you can choose to be private. Our privacy rating will help you select glass that works for you.